In a world where sustainability is no longer just a trend but a necessity, businesses across industries are re-evaluating their packaging choices. From the sweet treats we indulge into the luxurious cosmetics we pamper ourselves with, the packaging plays a crucial role in both protecting the product and presenting it in the most appealing manner. Among the many packaging options available, rigid boxes are emerging as a frontrunner for eco-conscious brands. Let’s dive into why rigid boxes are the future of sustainable, eco-friendly packaging and why brands in sectors like sweet boxes, macaroon boxes, cosmetic gift boxes, personal care sets, and luxury tea packaging should take note.

The Growing Demand for Sustainable Packaging

Sustainability has become a buzzword in recent years, but it is more than just a trend—it’s a fundamental shift in how we approach consumption and production. Consumers today are more aware than ever of the environmental impact of their choices. This awareness extends to packaging, where the demand for eco-friendly solutions is rising. Brands that align with this demand not only cater to a growing market of environmentally-conscious consumers but also position themselves as leaders in corporate responsibility.

Why Rigid Boxes?

Rigid boxes, known for their sturdy construction and elegant appearance, have long been favored for their ability to provide high-end presentation and protection. But beyond their aesthetic appeal, rigid boxes are now gaining traction for their sustainability credentials. Here’s why:

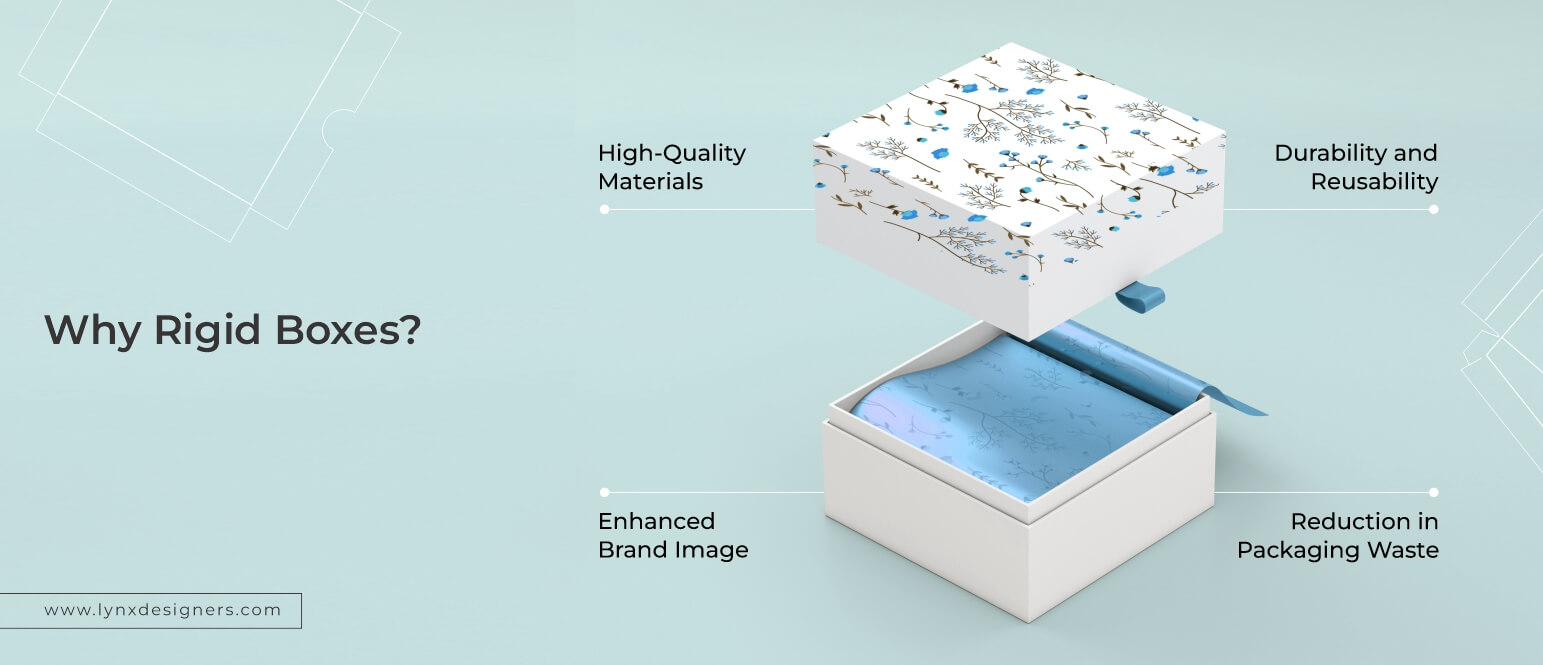

1. Durability and Reusability

Rigid boxes are built to last. Their durability means they are often reused, reducing the need for additional packaging and minimizing waste. Unlike flimsy alternatives that are easily discarded, a well-crafted rigid box can have a second life as a storage solution or keepsake, extending its utility beyond the initial product packaging.

2. High-Quality Materials

Many rigid boxes are made from recycled or sustainably sourced materials, making them a more eco-friendly choice compared to conventional packaging. For instance, high-quality cardboard used in rigid boxes can be sourced from responsibly managed forests or recycled paper. This not only reduces the carbon footprint but also supports sustainable forestry practices.

3. Reduction in Packaging Waste

The strength and structure of rigid boxes mean that they often require less additional packaging material. By minimizing the use of fillers and extra layers, these boxes help reduce overall packaging waste. This is particularly important in industries like luxury tea packaging and cosmetic gift boxes, where excess packaging can be a significant environmental concern.

4. Enhanced Brand Image

Using sustainable packaging like rigid boxes can significantly enhance a brand’s image. Consumers are increasingly looking to support companies that align with their values, including environmental responsibility. By choosing eco-friendly rigid boxes, brands in sectors such as sweet boxes and personal care sets demonstrate their commitment to sustainability, which can boost customer loyalty and differentiate them in a crowded market.

Industry-Specific Benefits

Sweets and Macaroon Boxes

In the confectionery industry, presentation is key. Rigid boxes offer a premium look and feel that enhances the consumer experience. For sweet and macaroon boxes, these sturdy packages protect delicate items while showcasing them beautifully. The ability to use recycled materials without compromising on aesthetics makes rigid boxes an ideal choice for eco-conscious confectionery brands.

Cosmetic Gift Boxes

Cosmetics often come in elaborate packaging, but sustainability can still be achieved without sacrificing luxury. Rigid boxes for cosmetic gift sets provide a high-end unboxing experience while supporting eco-friendly practices. Brands can opt for recycled or biodegradable materials and still deliver the elegance and protection their products require.

Personal Care Packaging

Personal care products are often associated with indulgence and self-care. By using rigid boxes made from sustainable materials, brands can align their packaging with the ethos of mindfulness and responsibility. This not only appeals to eco-conscious consumers but also reinforces the brand’s commitment to quality and sustainability.

Luxury Tea Packaging

For luxury tea brands, the packaging is as important as the product itself. Rigid boxes offer a sophisticated way to present premium tea while adhering to sustainable practices. The use of eco-friendly materials ensures that the packaging complements the high quality of the tea inside, all while minimizing environmental impact.

Rigid Boxes in India: A Growing Trend

In India, the trend towards sustainable packaging is gaining momentum. As more brands recognize the importance of eco-friendly solutions, the demand for rigid boxes is on the rise. Indian manufacturers are responding by offering a range of options that combine sustainability with high-quality craftsmanship. By choosing rigid boxes, Indian brands can not only meet the expectations of global consumers but also contribute to the country’s environmental goals.

Moving Forward with Rigid Boxes

For brand owners, project managers, and marketing heads, the choice of packaging is not just a functional decision but a strategic one. Embracing rigid boxes as part of a sustainable packaging strategy offers numerous benefits, from reducing environmental impact to enhancing brand image. By making the switch to eco-friendly rigid boxes, companies in the sweet, macaroon, cosmetic, personal care, and luxury tea industries can lead the charge towards a more sustainable future.

In conclusion, the future of packaging lies in sustainability, and rigid boxes are at the forefront of this movement. Their durability, reusability, and eco-friendly options make them an excellent choice for brands looking to align with the growing demand for responsible packaging. As we move towards a more environmentally-conscious era, embracing rigid boxes is not just a choice—it’s a responsibility and an opportunity to make a positive impact on the planet while delighting consumers with premium, sustainable packaging.

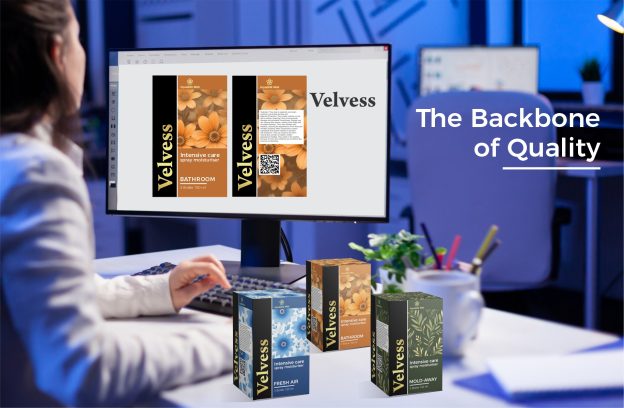

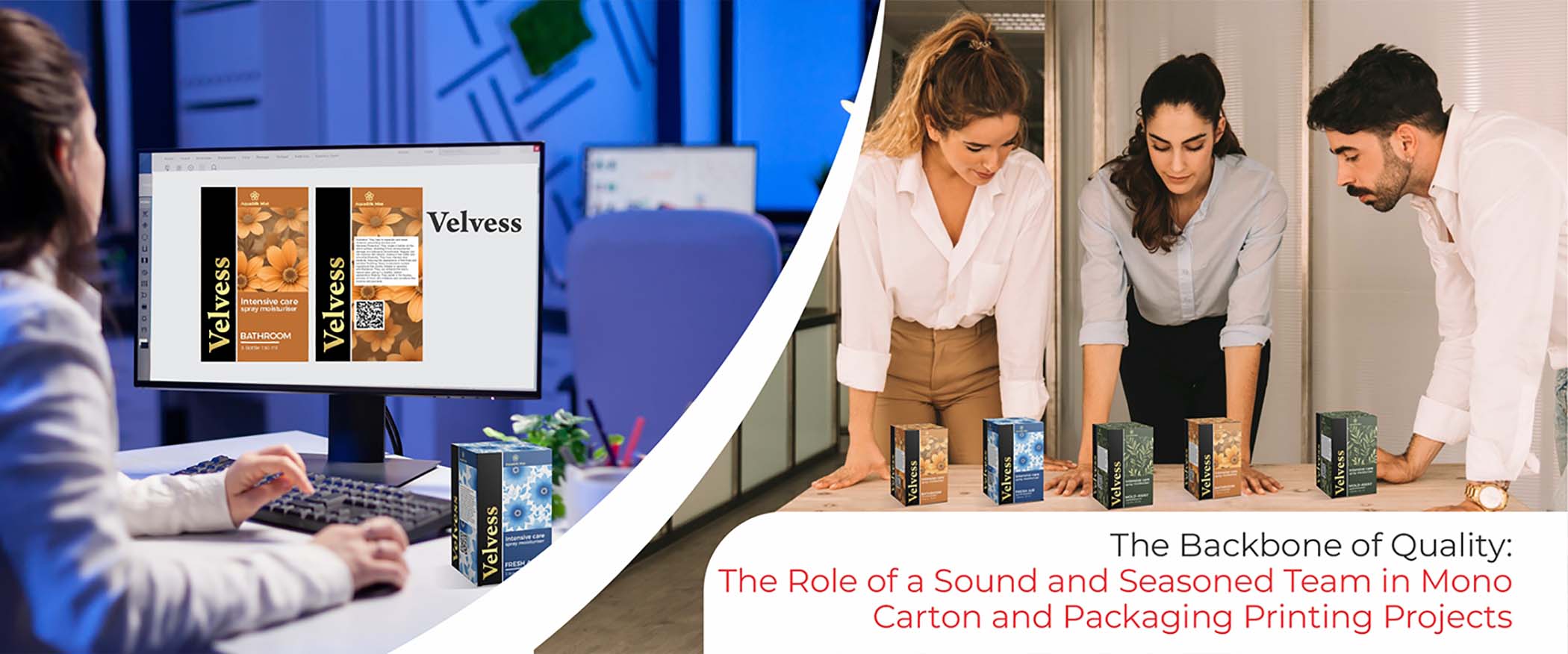

Mono-Carton Unveiled

Mono-Carton Unveiled The Advantages of Mono-Carton

The Advantages of Mono-Carton The Lynx Advantage

The Lynx Advantage