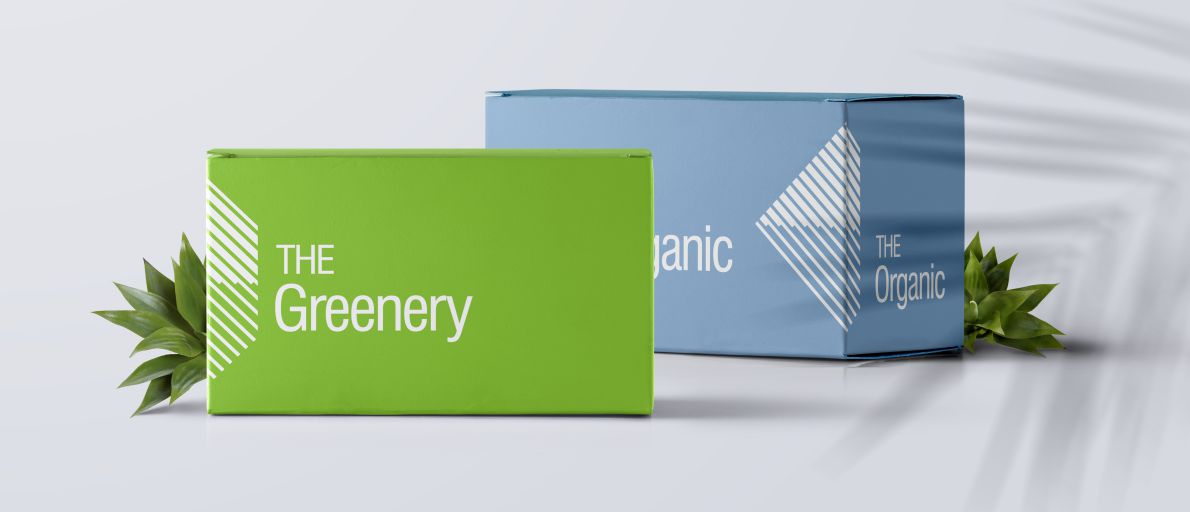

In the world of packaging, every box, carton, or container has a story to tell. The packaging serves as a visual storyteller that communicates a brand’s identity, values, and the essence of its product. This is where the art of packaging design comes into play. Among the various options available to packaging designers, the mono-carton has emerged as a versatile and captivating canvas for Lynx Designers and Creators, a packaging company that thrives on innovation and creativity.

Mono-Carton Unveiled

Mono-Carton Unveiled

Before diving into the mono-carton design world, let’s first understand what it is. A mono-carton is a single-layered, usually non-foldable carton made from a piece of paperboard or cardboard. It is often used to package various products such as cosmetics, pharmaceuticals, electronics, etc. The mono-carton’s simplicity and elegance have made it a favorite among packaging designers for its aesthetic appeal and functionality.

The Advantages of Mono-Carton

The Advantages of Mono-Carton

- Eco-Friendly: Sustainability is a buzzword in today’s packaging industry, and mono-cartons align perfectly with this trend. Being made from a single material, they are easy to recycle and minimize waste, reducing the brand’s carbon footprint.

- Versatility: Mono cartons come in various shapes, sizes, and finishes, allowing designers at Lynx to explore their creative boundaries. Mono-cartons can adapt to any style, whether a sleek and minimalist design or a bold and vibrant one.

- Brand Identity: Packaging is a powerful tool to convey a brand’s personality and values. Mono-cartons offer a clean canvas for designers to play with colours, typography, and graphics to create packaging that resonates with the brand’s identity.

- Cost-Effective: As mono-cartons are typically made from a single piece of material, they are cost-effective in production and material usage, making them an attractive option for businesses aiming to optimize their packaging costs.

The Lynx Advantage

The Lynx Advantage

Lynx Designers and Creators are experts in creating mono-carton packaging solutions that align with your brand’s vision and objectives. Here’s why you should consider Lynx for your packaging needs:

- Customization: Lynx offers tailor-made mono-carton designs that reflect your brand’s identity. Whether you require a sleek and modern look or a vintage-inspired design, they can bring your vision to life.

- Innovation: Lynx stays updated with the latest trends and technologies in the packaging industry. They can incorporate cutting-edge printing techniques, embossing, and unique finishes to make your mono-carton exceptional.

- Eco-Friendly Approach: Lynx is committed to sustainability. They use eco-friendly materials and production processes, helping your brand reduce its environmental impact.

- Quality Assurance: Lynx ensures the highest quality standards in their mono-carton production. Your products will be well-protected and visually appealing, enhancing customers’ overall experience.

Conclusion

In the packaging design, mono-cartons have emerged as versatile, cost-effective, and sustainable solutions that can elevate your brand’s image. Lynx Designers and Creators specialize in crafting unique and impactful mono-carton designs that resonate with your target audience. By choosing Lynx, you can enhance your brand’s packaging, reduce your environmental footprint, and stand out in a competitive market. Embrace the mono-carton revolution and let Lynx help you create packaging that speaks volumes about your brand.